Quality Control Measures

At Kubota Rice Industry (SGP), we implement the following measures to ensure that our production is safe and reliable.

Brown Rice Sampling and Inspection

We perform the following sample inspections on the Kubota Rice Industry (SGP) rice immediately after it is imported into Singapore, while it is still in the brown rice state.

|

Measurement of Radioactive ConcentrationWhen brown rice arrives for storage, samples by different producers and shipping dates are taken and the radioactive concentration is measured to confirm the product safety. |

|

Measurement of Brown Rice QualityThe contamination rate of defective rice is measured using a grain discriminator. We work to ensure stable quality from the brown rice stage. |

|

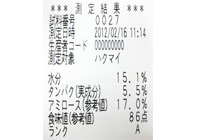

Measurement of Taste ValueA taste meter that quantifies the deliciousness of the rice is used to manage the deliciousness from the brown rice state by each different producer and shipping date. |

Sampling and Inspection after Rice Polishing

To ensure that the rice delivered to customers has stable quality, we check the quality again when the rice polishing is completed.

|

Measurement of Taste ValueA taste meter that quantifies the deliciousness of the rice is used again to manage the quality for each session of rice polishing. |

|

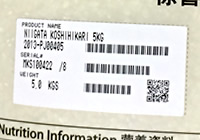

Product Management Using BarcodesEach individual product to be delivered is managed using a serial number for each separate rice polishing session and we manage and record all of the production history from the rice production to the delivery. |