Introduction to Facilities

Rice Polishing Equipment at Kubota Rice Industry (SGP)

The majority of the Japanese rice that is consumed overseas is polished where it has been grown in Japan before it is transported and sold.

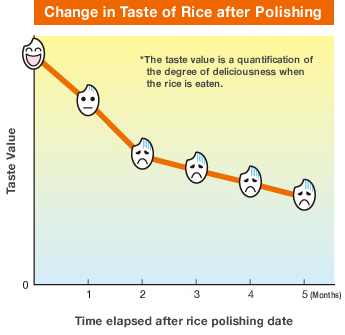

However, the ideal time to eat rice is immediately after polishing it. The quality deteriorates as time passes after the polishing and the taste value declines.

To avoid this problem, Kubota Rice Industry (SGP) has installed professional rice polishing equipment from Japan. By installing this equipment in Singapore, it is possible to transport the rice in the brown rice state and then polish it immediately before selling and delivering it to customers.

* Results of Testing to Judge Rice Freshness (Nouminren Food Research Laboratory pH Evaluation Method Kit) *

The test agent is added to cause a reaction.

Fresh rice produces a green color. Rice which has passed over time changes to orange color because of oxidation.

Three months after the polishing of the rice, it can be seen that the oxidation has progressed.

This result also shows that it is recommendable to eat rice as quickly as possible after it has been polished.

Professional Rice Polishing Equipment for Commercial Use

Although we just say “rice polishing,” this can refer to a wide variety of equipment, ranging from devices for household use and simple rice polishers for store use all the way up to commercial rice polishing equipment that has sophisticated quality control functions.

Of course, there are great differences in the performance levels of these different rice polishers and naturally this affects how delicious the rice is after it has been cooked.

The rice that is harvested from a rice field will include a percentage of defective rice that will affect the quality of the cooking results, such as colored rice and broken rice. In order to supply delicious rice, it is necessary to reliably remove this defective rice.

Kubota Rice Industry (SGP) has installed all the equipment necessary to perform high quality rice polishing. This includes color sorting equipment to remove colored rice and equipment to remove small rice, which has a detrimental effect on the taste of the cooked rice. This equipment enforces rice polishing quality at the same level or even greater than those produced in Japan.

Rice Mixing EquipmentVarious types of rice are mixed uniformly to ensure stable quality. |

Rice Polishing EquipmentCommercial rice polishing equipment's excellent low temperature rice polishing technology preserves the deliciousness of the rice. |

Color Sorting EquipmentItems such and glass and stones that are mixed into the rice are removed. |

Equipment to Remove Small RiceRice that has inferior quality is removed, such as small rice and broken rice. |

Weighing and Bagging Machine EquipmentThe rice that has been carefully polished is then measured precisely. |

|

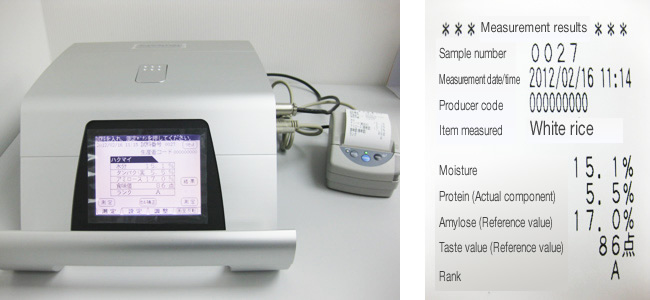

Additional efforts are made to stabilize the polished rice quality, such as with a taste meter to score and display the deliciousness of the rice and a whiteness meter to maintain stable rice polishing quality. We have also installed various inspection equipment such as radiation measuring equipment as we are aiming for safe and reliable production.

With all this equipment and the full strength of Kubota Group and its deep involvement in agriculture, we will supply Japanese rice to the Singapore market in its most delicious state.